News

10

Dec

Diagnosing Inconsistent Seals in Custom Plastic Packaging and How Octagonal Bags Help

Diagnosing Inconsistent Seals in

Custom Plastic Packaging and How Octagonal Bags Help

You may see seals that do not work well in custom plastic packaging. This happens because of sealing pressure, material alignment, and equipment settings. The table below lists common causes:

Cause | Explanation |

Wrinkles & Creases | Sealing jaws can break film at wrinkles. This makes seals weak. |

Improper Clearance | Wrong clearance gives uneven pressure. This can split seals. |

Misalignment | Sealing jaws that are not lined up cause seal problems. |

Backlash | Backlash between jaws makes sealing less steady. |

Sealing Jaw Design | Bad design gives uneven pressure and can break seals. |

Cangzhou Dingnuo Plastic Packaging Co., Ltd. knows these problems. They offer new ideas like octagonal sealed bags. These bags fix these issues and help your business do well.

Key Takeaways

Look for seal problems like wrinkles, misalignment, and wrong pressure to keep products safe. Check sealing machines often and adjust them to keep pressure and heat steady for strong seals. Pick materials that work well together to stop leaks and make packaging last longer. Think about using octagonal sealed bags because they are strong, stable, and help stop leaks. Make octagonal bags match your brand and follow safety rules for food and chemicals.

Common Seal Issues in custom plastic packaging

When you use custom plastic packaging, you might see seal problems. Knowing about these problems helps keep products safe and fresh. Here are some main causes.

Pressure and Temperature Fluctuations

You need the right pressure and temperature for strong seals. If these change a lot, seals can get weak or leak. Tests show that uneven pressure often causes leaks. Machines like flow wrappers make it hard to keep pressure steady. This can hurt seal quality. Heat, time, and pressure all matter. Changing these settings can help you get better seals.

Here is a table that shows how pressure and temperature affect seals:

Issue | Impact on Seal Integrity |

Leaks and weak seals | |

Heat, time, and pressure relationships | Better adjustments lead to stronger seals |

Design adjustments (e.g., FLEX jaws) | Adapts to thickness, reduces damage from excess pressure |

Material Alignment Problems

You need to line up materials before sealing. If layers do not match, seals can split or fail. Wrinkles and creases also cause trouble. You can stop these by checking the film and making sure it is smooth. Good alignment helps you save products and makes packaging look nice.

Equipment Calibration Errors

Your sealing machines need regular checks. If machines are not set right, you get uneven pressure or temperature. This can break seals or make them leak. You should check and fix machines often. Well-kept machines give you better results in custom plastic packaging.

Tip: Set reminders to check your equipment. This easy step can save you time and money.

Material Compatibility

You need to pick materials that work well together. Some films do not seal with certain adhesives or heat. If you use the wrong mix, seals may not last. Always test new materials before big jobs. This helps you avoid mistakes and keeps products safe.

When you know these common problems, you can fix them. Good factories like Cangzhou Dingnuo Plastic Packaging Co., Ltd. help you solve these issues and give expert help for your custom plastic packaging needs.

Diagnosing and Troubleshooting Seals

You want strong and reliable seals in your custom plastic packaging. You can follow a step-by-step approach to find and fix seal problems. This guide helps you keep your products safe and your packaging looking professional.

Visual Inspection Steps

Start by looking at your sealed packages. You can spot many problems with your eyes. Check for wrinkles, gaps, or uneven edges. Hold the package up to the light. You may see thin spots or holes. Run your fingers along the seal. Feel for bumps or weak areas. If you find any, set those packages aside for further testing.

Tip: Use a checklist during inspection. This helps you catch every detail and keeps your process consistent.

Seal Strength Testing

You need to know if your seals can handle stress. Try a simple pull test. Hold both sides of the seal and pull gently. A strong seal will not break or open. You can also use water immersion. Place the sealed package in water and squeeze it. Watch for bubbles. Bubbles mean leaks. For more accuracy, use a seal strength tester. This machine measures how much force the seal can take before breaking.

Test Method | What It Checks | How To Use It |

Pull Test | Seal strength | Pull both sides gently |

Water Immersion | Leak detection | Squeeze in water |

Seal Strength Tester | Breaking force | Use machine for results |

Equipment Adjustments

Your sealing equipment needs regular care. Check the temperature and pressure settings. Make sure the sealing jaws line up correctly. Clean the jaws often. Dust or leftover material can weaken seals. Calibrate your machines on a schedule. Write down the settings that work best for your materials. If you see repeated problems, adjust one setting at a time. Test after each change.

Note: Well-maintained equipment gives you better results and saves you money over time.

Material Solutions

Choose the right materials for your packaging. Some films work better with certain adhesives or heat levels. Test new materials before using them for large orders. Ask your supplier about compatibility. International standards help you pick safe and high-quality materials. For example, ISO 15378:2017 sets rules for packaging used in medicine. These rules make sure your packaging is safe and strong.

Standard | Description |

ISO 15378:2017ISO 15378:2017 | Sets quality rules for packaging materials in medicine. Ensures safety. |

You can trust factories that follow these standards. They care about your product’s safety and quality. When you use custom plastic packaging, you get packaging that meets strict rules and keeps your products secure.

Callout: Always ask your supplier about compliance with international standards. This protects your brand and your customers.

By following these steps, you can find and fix seal problems quickly. You keep your products fresh and your customers happy. Reliable packaging builds trust and helps your business grow.

Octagonal Bags: Sealing Solutions

Design Advantages

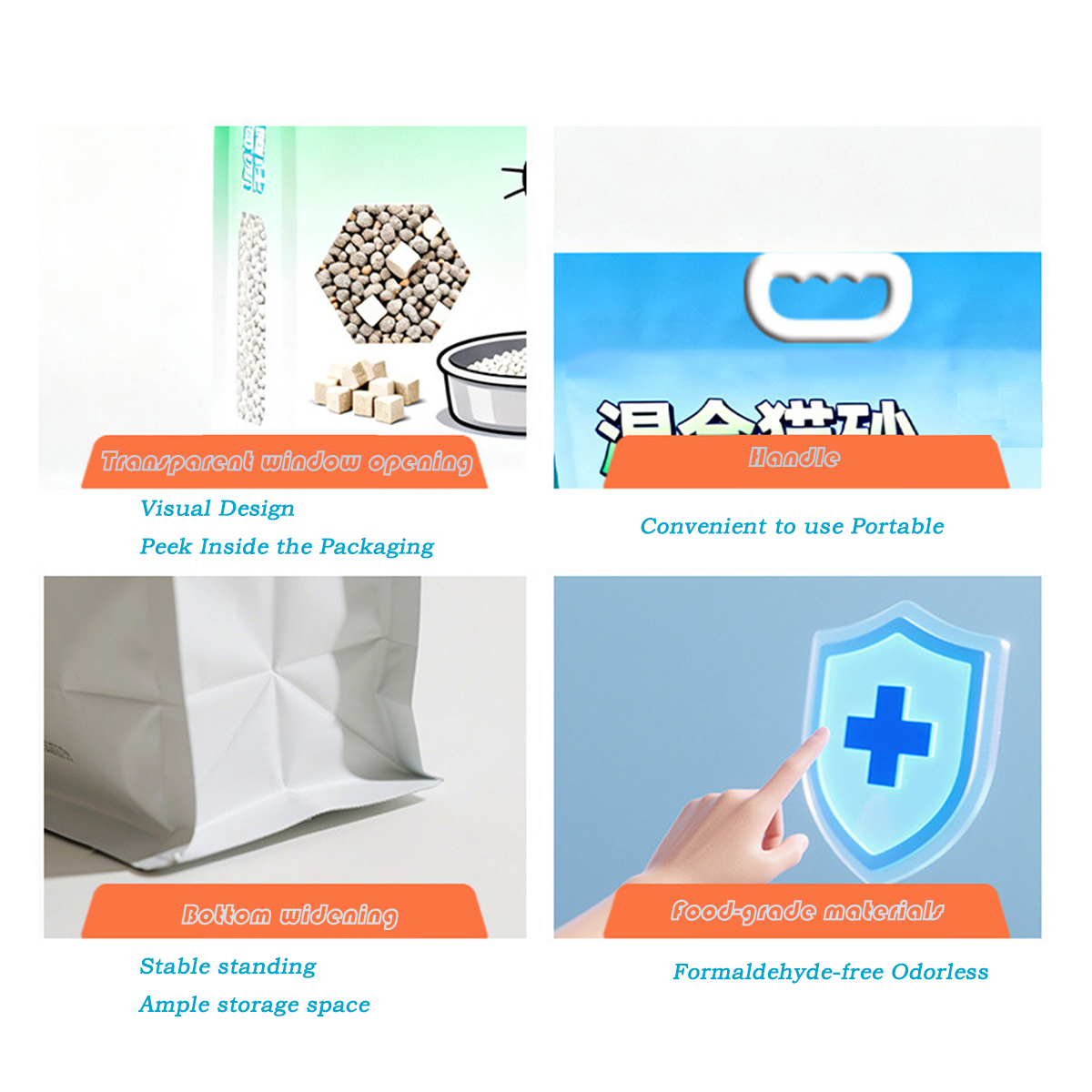

You want packaging that looks good and keeps products safe. Octagonal sealed bags from Cangzhou Dingnuo Plastic Packaging Co., Ltd. have special design features. These features help fix common sealing problems. The octagonal sealing edges make strong seals that do not tear easily. The base lets the bag stand up straight. This makes products easy to show on shelves. The folded sides make the bag steady and give it a 3D shape. These design choices stop weak seals and help your packaging look neat.

Good octagonal bags are very strong. When you use these bags, you see they do not rip easily. The heat seal is so strong that if the bag tears, it happens at the edge. The middle stays safe. This means the seal works well and does not leak. You get better sealing and fewer problems.

Tip: Pick bags with strong edges for more safety when shipping and storing.

Durability and Leak Prevention

You need packaging that keeps products fresh and safe. Octagonal sealed bags use new materials and sealing methods. These bags stop leaks and keep out water, air, and dirt. The strong seals keep things inside safe, even during shipping or storage.

Cangzhou Dingnuo Plastic Packaging Co., Ltd. checks every batch to make sure the bags are high quality. You can use these bags for food, pet items, and daily chemicals. The strong octagonal bags help you avoid losing products and getting complaints.

Comparison with Other Bag Types

You might wonder how octagonal bags are different from other bags. Flat bags and pillow bags often have weak seals at the corners. They do not stand up well, so they are hard to display. Gusseted bags hold more but can lose shape and leak at the folds.

Octagonal sealed bags fix these problems. The special sealing edges and folded sides make the bag stand up and stay steady. You get better protection and a nicer look. The 3D shape helps your products stand out in stores.

Bag Type | Seal Strength | Stability | Presentation | Leak Prevention |

Flat Bag | Moderate | Low | Basic | Moderate |

Pillow Bag | Moderate | Low | Basic | Moderate |

Gusseted Bag | Good | Moderate | Good | Moderate |

Octagonal Bag | Excellent | High | Premium | Excellent |

Octagonal Bags for custom plastic packaging

You want packaging that meets world standards and fits your needs. Octagonal sealed bags from Cangzhou Dingnuo Plastic Packaging Co., Ltd. have important certifications. You can use them for food, chemicals, and pet items in many places.

Certification/Standard | Region/Applicability |

Global | |

ISO 14001 | Global |

EU No 10/2011 | European Union |

US FDA standards | United States |

SNI certification | Southeast Asia |

EAC certification | Russia/Central Asia |

Localized requirements | Japan, South Korea, Latin America, Africa |

You save money when you buy a lot at once. The factory sells directly, so your costs go down by 10-30%. You can pick the size, pattern, and logo to match your brand. Fast shipping helps you get your packaging quickly.

If you have seal problems or want your products to look better, try octagonal sealed bags. You get strong seals, good protection, and a nice look. Cangzhou Dingnuo Plastic Packaging Co., Ltd. works to solve your problems and gives great service. You earn trust from customers and grow your business with high-quality custom plastic packaging.

Callout: Good packaging keeps your products safe and customers happy. Pick options that help your business do well.

You can fix seal problems by looking at packages. You should test how strong the seals are. Make changes to your equipment if needed. Octagonal sealed bags from Cangzhou Dingnuo have strong seals. These bags also look professional. If you pick these bags, you get good quality. You also get fast service. Check the printing quality before you switch. Make sure the materials are safe. Test how strong the seals are. Keep your packaging in a cool, dry place. You can trust Cangzhou Dingnai. They help your business grow with good solutions and great customer care.

FAQ

What causes seals to fail in custom plastic packaging?

Seals can fail if pressure is not even. Bad material alignment also causes problems. Wrong equipment settings make seals weak. Check your machines often. Use good materials to stop these issues.

How do octagonal bags improve seal strength?

Octagonal bags have special sealing edges. They use strong materials. These features give better protection. You see fewer leaks. The design keeps products fresh and safe.

Can I customize octagonal bags for my brand?

You can pick the size you want. You can choose a pattern and logo. Cangzhou Dingnuo gives many choices. You can match your brand and product needs.

Are octagonal bags safe for food and chemicals?

Octagonal bags follow US FDA and EU rules. You can use them for food and pet supplies. They work for daily chemicals too. The factory checks every batch for safety.

How quickly can I receive my order?

You get fast shipping from Cangzhou Dingnuo. The factory sends orders directly. You save time and money when you buy in bulk.